What Are Jump Stitches and How to Reduce Jump Stitches in Digitizing?

Jump stitches are a common term in embroidery digitizing that refer to the threads connecting one part of a design to another without being stitched into the fabric. These are the paths that embroidery machines follow to transition from one section of a design to another. While jump stitches are sometimes necessary, they can negatively affect the final appearance of the design if not managed properly. In this blog, we will explore what jump stitches are, why they occur, and practical ways to reduce them in digitizing. We will also touch upon how effective digitizing techniques, including vector services, can make a difference in creating professional-quality embroidery designs.

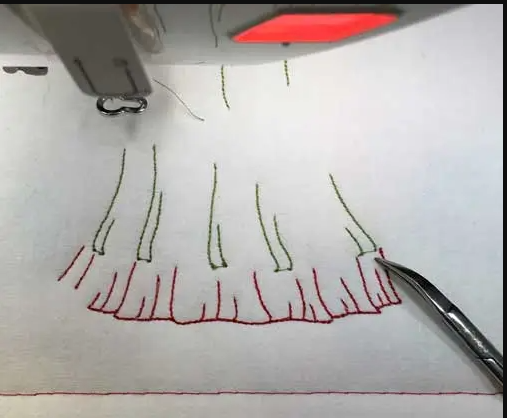

Understanding Jump Stitches

In the context of embroidery digitizing, jump stitches occur when the machine needle travels from one point of the design to another without stitching. This movement creates a loose thread, known as a jump stitch, across the fabric’s surface. These threads do not anchor into the material, so they must be trimmed manually or by the embroidery machine.

Jump stitches are most common in designs with multiple colors, intricate patterns, or scattered elements. For instance, a logo with small letters separated by significant spaces might require jump stitches for the machine to move between letters. Although necessary in such cases, minimizing jump stitches is critical for improving the design’s overall quality and professionalism.

Why Do Jump Stitches Occur?

Jump stitches arise due to the limitations of embroidery machines and the design itself. Several factors contribute to their occurrence:

- Design Complexity: Complex designs with scattered elements or multiple sections naturally require the machine to move between these areas, resulting in jump stitches.

- Color Changes: Designs with multiple thread colors increase the likelihood of jump stitches, especially when elements of the same color are far apart.

- Improper Digitizing: Poor digitizing practices, such as not sequencing the stitching path efficiently, can lead to unnecessary jump stitches.

- Machine Limitations: Some older or basic embroidery machines may not have advanced features to minimize jump stitches automatically.

The Impact of Jump Stitches on Embroidery Quality

Excessive jump stitches can significantly affect the quality of an embroidered design. Here are the primary issues caused by unmanaged jump stitches:

- Messy Appearance: Loose threads across the fabric make the design look untidy and unprofessional.

- Increased Trimming: Manual trimming of jump stitches increases production time and labor costs.

- Snagging Risk: Untrimmed threads may snag during handling or washing, potentially ruining the design.

- Inconsistent Stitching: Too many jump stitches can disrupt the uniformity of the design, especially in detailed areas.

Reducing jump stitches ensures a cleaner, more polished result and improves the overall efficiency of embroidery production.

How to Reduce Jump Stitches in Digitizing

Minimizing jump stitches requires a combination of effective digitizing techniques, proper machine setup, and thoughtful design planning. Let’s break down the steps to achieve this:

1. Optimize Design Pathing

Efficient pathing involves planning the stitching sequence to minimize the needle’s travel distance. Group similar elements together and sequence them logically to reduce unnecessary movements. For instance, digitizing letters in a continuous path rather than jumping between non-adjacent letters can significantly reduce jump stitches.

2. Use Auto-Trimming Features

Modern embroidery machines often come equipped with automatic trimming features. When activated, the machine trims jump stitches automatically, saving time and improving the design’s appearance. Ensure that your machine’s auto-trim function is properly configured and maintained.

3. Adjust Stitch Density

In some cases, adjusting the stitch density can help reduce the need for jump stitches. Overly dense designs might require more jumps to avoid overlapping stitches. Striking a balance between sufficient coverage and minimal jumps is key.

4. Utilize Professional Digitizing Services

Professional digitizing services, such as those specializing in digitizing in USA, can help create designs with minimal jump stitches. Skilled digitizers use advanced software to map out efficient stitching paths and optimize the design for embroidery. They also ensure compatibility with modern embroidery machines.

5. Avoid Excessive Color Changes

Minimizing color changes in a design can help reduce jump stitches. Group elements of the same color together and sequence them logically to limit machine movement.

6. Leverage Vector Services

Vector services play an essential role in preparing designs for embroidery. Converting artwork into a clean, scalable vector format allows for precise digitizing. This ensures that elements are positioned optimally, reducing the need for jump stitches. High-quality vector art makes it easier for digitizers to create efficient designs without unnecessary travel paths.

7. Regular Machine Maintenance

A well-maintained embroidery machine performs more accurately, reducing unnecessary jumps. Keep your machine’s needles, thread tension, and software in optimal condition to ensure smooth operation.

Choosing the Right Digitizing Partner

Reducing jump stitches often requires expertise in digitizing and design optimization. Partnering with a professional digitizing company ensures high-quality results. Companies offering services like digitizing in USA often employ advanced software and skilled professionals to create flawless embroidery designs. By outsourcing digitizing work to experts, you can focus on other aspects of your business while ensuring top-notch embroidery quality.

Conclusion

Jump stitches are an inevitable part of embroidery, but their impact can be minimized through effective digitizing techniques and thoughtful design practices. By optimizing stitching paths, leveraging modern machine features, and utilizing vector services, you can create professional-quality embroidery designs with minimal jump stitches.

Partnering with experienced digitizing professionals ensures that your designs are efficient, visually appealing, and production-ready. Whether you’re looking to reduce production time or improve the quality of your embroidered products, understanding and addressing jump stitches is a crucial step toward achieving excellence in embroidery digitizing.